Technology Presentation

| |

|

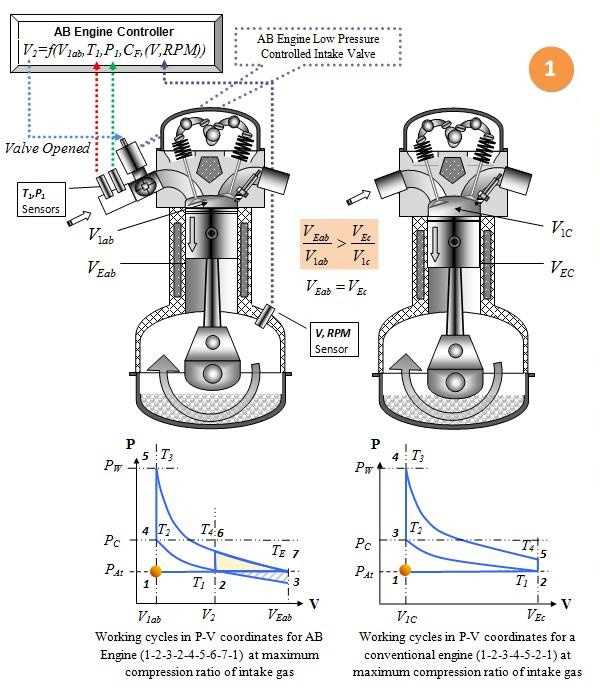

Intake Stroke Stage - 1

At this stage both engines are ready to be filled by intake gas and:

· High pressure Valves of both engines are opened

· AB Engine low pressure intake Valve is opened

· AB Engine controller collects Intake gas data, Temperature (T1) and Pressure (P1). In a regular car engine, T1 and P1are at atmospheric air temperature and pressure

· AB Engine controller collects data on RPM and piston position V

· AB Engine is preset with Coefficient CF that takes into account behavior of fuel used within the engine. For gasoline fuel, it reflects what Pressure and Temperature is critical for fuel detonation. For Diesel fuel, it accounts for Temperature and Pressure for self ignition at the end of the compression Stroke

· Taking into account all the data mentioned above, AB Engine controller calculates the V2 piston position for the next stage of the intake stroke

· The conventional engine is preset with maximum compression ratio at maximum working cycle output such that the fuel used is never detonated or in the case of Diesel, always ignites.

· At this stage, AB Engine has no limit to the type of fuel used or the Octane rating of Gasoline. CF provides information for the AB Engine controller regarding the fuel type, and the Controller provides the V2 piston position parameter that is necessary to satisfy fuel conditions.

· The conventional engine has no ability to freely change the intake gas compression ratio so the maximum engine compression ratio V1/VC is preset as is the minimum for the harshest atmospheric conditions (assuming customer uses gasoline fuel with minimum Octane rating).

|

AB Engine Incorporated introduces a New Method (AB Engine Method) to convert burning gasoline, gas or diesel fuels into mechanical energy while still within the bounds of the conventional Otto, Miller, Diesel or similar internal combustion engine (ICE) design constraints. The new method allows for an ICE design with the highest fuel efficiency theoretically possible.

Saturday, October 26, 2013

AB Engine Technology Presentation

Subscribe to:

Post Comments (Atom)

No comments:

Post a Comment