About Us

AB Engine Incorporated is an intellectual property based company that has developed the AB Engine. The AB Engine is an innovative internal combustion engine (ICE) whose efficiency will significantly surpass that of conventional ICE and Diesel designs on the market today. The AB Engine is also an ideal “value-add” to the emerging Hybrid and Advanced Diesel automobile designs, leading to unparalleled mileage per gallon improvements. Contrary to using specialized and expensive high-octane based fuels combined with a complicated engine design, as much of the product's competition currently does to obtain higher efficiency, the AB Engine is based on a modified and well known Otto and Diesel engines design that is capable of utilizing inexpensive low-octane based fuels to achieve unparalleled efficiency. This efficiency results in 25 to 40 percent fuel economy over existing gasoline and diesel engine designs as well as a reduction in greenhouse gas emissions.

|

AB Engine Incorporated introduces a New Method (AB Engine Method) to convert burning gasoline, gas or diesel fuels into mechanical energy while still within the bounds of the conventional Otto, Miller, Diesel or similar internal combustion engine (ICE) design constraints. The new method allows for an ICE design with the highest fuel efficiency theoretically possible.

Saturday, October 26, 2013

AB Engine Technology Presentation

Technology Presentation

| |

|

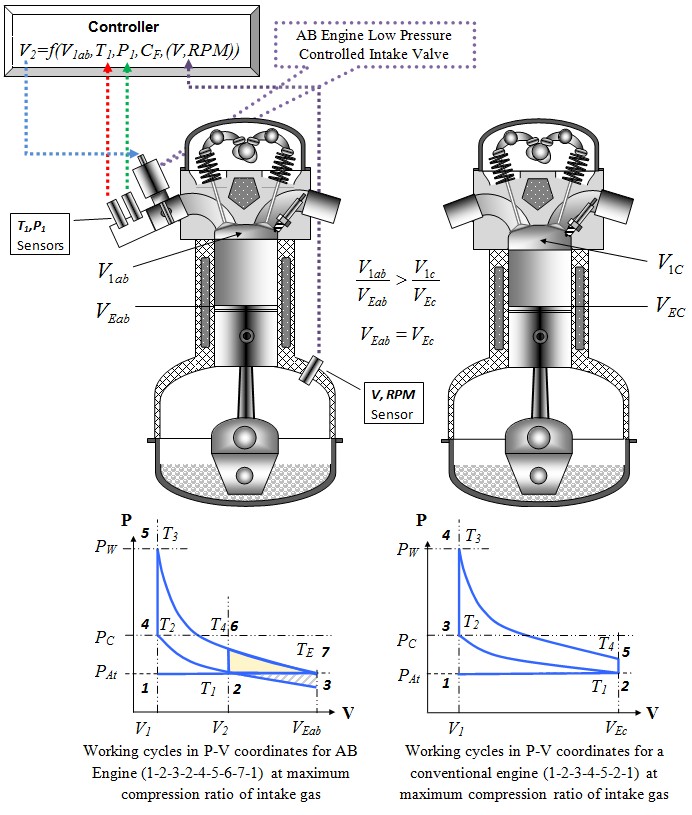

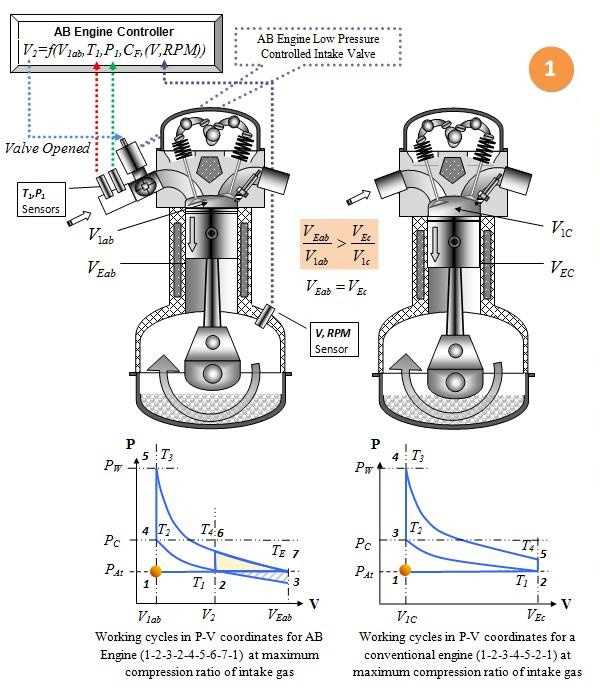

Intake Stroke Stage - 1

At this stage both engines are ready to be filled by intake gas and:

· High pressure Valves of both engines are opened

· AB Engine low pressure intake Valve is opened

· AB Engine controller collects Intake gas data, Temperature (T1) and Pressure (P1). In a regular car engine, T1 and P1are at atmospheric air temperature and pressure

· AB Engine controller collects data on RPM and piston position V

· AB Engine is preset with Coefficient CF that takes into account behavior of fuel used within the engine. For gasoline fuel, it reflects what Pressure and Temperature is critical for fuel detonation. For Diesel fuel, it accounts for Temperature and Pressure for self ignition at the end of the compression Stroke

· Taking into account all the data mentioned above, AB Engine controller calculates the V2 piston position for the next stage of the intake stroke

· The conventional engine is preset with maximum compression ratio at maximum working cycle output such that the fuel used is never detonated or in the case of Diesel, always ignites.

· At this stage, AB Engine has no limit to the type of fuel used or the Octane rating of Gasoline. CF provides information for the AB Engine controller regarding the fuel type, and the Controller provides the V2 piston position parameter that is necessary to satisfy fuel conditions.

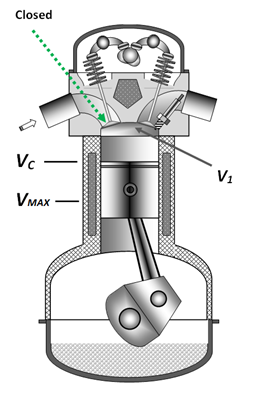

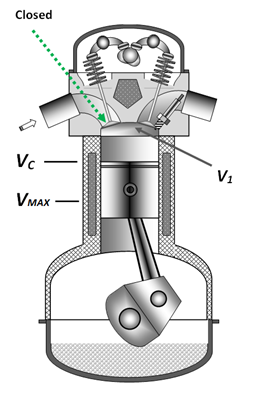

· The conventional engine has no ability to freely change the intake gas compression ratio so the maximum engine compression ratio V1/VC is preset as is the minimum for the harshest atmospheric conditions (assuming customer uses gasoline fuel with minimum Octane rating).

|

AB Engine Inc. Licensing Portfolio

NOVELTYTECHNIQUES (METHODS) TO OPTIMIZE EXISTING INTERNAL COMBUSTION ENGINES EFFICIENCY AND PERFORMANCE

IMPORTANCESTRATEGIC IP FOR AUTO, POWER GENERATOR, MACHINERY, AND SHIP BUILDING ENGINE MANUFACTURERS

FUEL-EFFICIENT INTERNAL COMBUSTION ENGINE AB Engine Incorporated

Since it was first developed more than a century ago, the performance of internal combustion engines (ICE) has suffered from low thermal efficiency mostly due to the low compression-expansion ratios of burnt fuels. AB Engine Incorporated introduces an innovative method that more efficiently converts thermal energy from burned gas, gasoline and diesel fuels into mechanical energy without exceeding the constraints of conventional ICE designs (e.g., Otto and Miller).

Value Proposition:

The disclosed portfolio describes the most efficient ICE engine theoretically possible, increasing efficiency 20-45% over existing ICE technology. In addition to marked improvements in efficiency, the AB Engine method reduces noise, engine temperature and exhaust gas pressure, while increasing linear output power with respect to RPM. Moreover, the AB Engine is compatible with different fuel types and intake gas conditions, as well as Hybrid and Turbocharged engine designs. The AB Engine improves both efficiency and performance without the disadvantages of alternative designs which involve complex mechanical solutions.

The disclosed portfolio describes the most efficient ICE engine theoretically possible, increasing efficiency 20-45% over existing ICE technology. In addition to marked improvements in efficiency, the AB Engine method reduces noise, engine temperature and exhaust gas pressure, while increasing linear output power with respect to RPM. Moreover, the AB Engine is compatible with different fuel types and intake gas conditions, as well as Hybrid and Turbocharged engine designs. The AB Engine improves both efficiency and performance without the disadvantages of alternative designs which involve complex mechanical solutions.

Priority Date: 05-29-2007

List of “IP”

IP is a bundle of US patent and several international patent applications of the same invention:

Title: “itemprop="brand" itemscope itemtype="http://schema.org/Brand"High efficiency Internal Combustion engine”

Inventor: Alexander Bakharev

Priority: U.S. Serial No. 12/129,595 (3136.001), filed May 29, 2008, which claims priority to U.S. Prov. Appl. No. 60/940,646, filed May 29, 2007

U.S. Serial No.: 13/300,133

2.

U.S. Continuation Patent #8,396,645 March 12, 2013

Title: HIGH EFFICIENCY INTERNAL COMBUSTION ENGINE

Inventor: Alexander Bakharev

Priority: U.S. Serial No. 12/129,595 (3136.001), filed May 29, 2008, which claims priority to U.S. Prov. Appl. No. 60/940,646, filed May 29, 2007

U.S. Serial No.: 13/300,133

3. European Application “High efficiency Internal Combustion engine” No. 08769823.9 filed December 28, 2009 based on PCT Appl. No. PCT/US2008/065161 filed May 29, 2008

4. Chinese Patent # ZL 2008 8 0100951.9. November 14, 2012 based on Application “High efficiency Internal Combustion engine” No. 200880100951.9 international filling date January 29, 2010 based on PCT Appl. No. PCT/US2008/065161 filed May 29, 2008

Patent and all patent applications are assigned to AB Engine Incorporated.

AB Engine Technology and Technology Applications

This blog describes several possible design realizations of the fuel efficient AB Engine depending on the Internal Combustion Engine (ICE) application. We would like to emphasize that independent of which design solution is implemented, the AB Engine Method will create the most fuel efficient ICE engine theoretically possible! AB Engine is similar in fuel efficiency to the Atkinson engine, but does not have the disadvantages of implementing a complex mechanical solution. The AB Engine method also delivers many “collateral” advantages beyond the improvement in fuel efficiency such as low noise or silent engines, low temperature and pressure exhaust gases (eco friendly), linear power output with respect to RPM as well as adaptable solutions to different fuel types and intake gas conditions.

The main idea protected by patent consist of two parts.

- Ratio of maximum chamber volume to the minimum R=VMAX/VMIN is higher than critical volume VC for particular fuel type. Definition of critical Volume is given in US patent first claims#8,086,386

It is important to understand that R is not theoretically limited, it can be as high as desired from fuel efficiency point of view for one cycle at maximum power output. Practically, it is limited by the ratio at which the expanding burnt gas-fuel mixture reaches the environmental exhaust pressure PATM at volume VE. and temperature TE The ratio R can be even higher for engine designs that utilize different kinds of fuel.

- Engine designs that utilize the second part of the method admit oxidizing gas to the combustion chamber with a gas mass that is less than equivalent to “Critical Volume - VC” at initial gas temperatureT1 and pressure PATM.

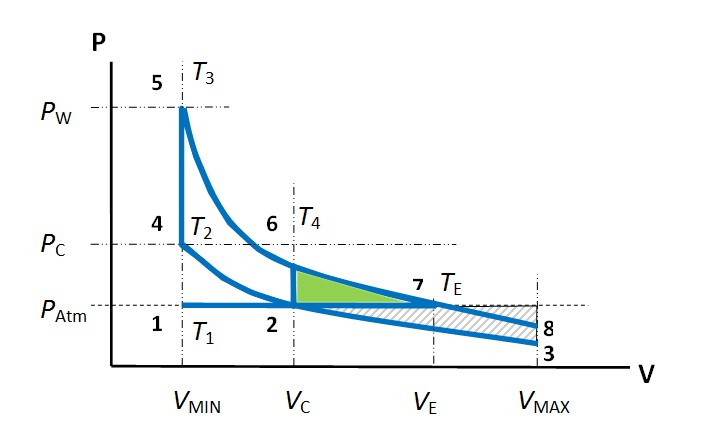

P-V Diagram (on the right) shows The "Alexander Bakharev (AB) engine P-V Cycle" of ICE at maximum power output. Diagram is outlining conventional engines (Otto, Diesel) cycles 1-2-4-5-6-2 and AB Engine Cycle 1-2-3-2-4-5-6-7-8-7

Green area 2-6-7 represent additional power generated by AB Cycle compare to conventional engine defining higher AB engine fuel efficiency

Some possible design solutions:

Solution 1.

Engine design with fixed high pressure Intake valve closing at a fixed level allowing gas intake below Critical volume. This solution is well described in the patent with step by step analysis of the Thermodynamics behind the method. (Picture bellow)

Applications: Excellent solution for stationary or mobile power generators such as:

- Houses or offices

- Boats, yachts and large ships (marine applications)

- Hybrid solutions for cars and trucks

Advantages:

- The most inexpensive implementation of the AB Engine Method and does not require the design of unique engine parts.

- Excellent Design for an ICE in Power generators with fixed RPM and particular fuel type.

Disadvantages:All the disadvantages of ICEs with fixed intake valves such as:

- Declining power output with increase in RPM; this is not a disadvantage for Power Generators since they can be designed and optimized for a particular engine RPM.

- Inability to adjust actual compression ratio to particular type of fuel or intake gas temperature and pressure.

Solution 2.

Engine design with Time Variable Valve (TVV)This is a solution that requires almost no changes to an existing engine that is already equipped with TVVs and PC controllers. There is a need however to reprogram the controller for specific parameters (variables) that are essential for executing the AB Engine Method. It is also necessary to implement sensors such that measure: temperature, pressure, RPM, fuel type, combustion chamber and piston positions. Many sensor solutions are already used in modern day technologies and they can be adapted to the AB Engine Method.Applications:This is an excellent solution for cars, motorcycles, trucks, airplanes and mobile Power generators ICEs. This variant is suited for extreme weather conditions and large altitude and atmospheric temperature/pressure changes.

Advantages:

- Excellent for extreme weather conditions and large altitude and atmospheric temperature/pressure changes.

- The TVV and PC controller make this solution adaptable to almost any type of application.

- Great engine dynamics

- Easy to adapt to any fuel type

- Engine can start up with gasoline and continue with Diesel

- Easy to adapt to an existing TVV technology

Disadvantages:

- High temperature and High pressure control valve is expensive solution.

Solution 3.Engine design with an AB Engine Controlled Valve or Damper. This solution is well described in the section of "Technology Presentation" with step by step analysis of the P-V diagram behind the method.

This is one of the AB Engine team's favorite solutions. This technology is similar to TVVs, but has a different and unique implementation. This technology is described in detail in our ‘Technology Presentation” section, but there we did not disclose all the advantages of this variation.Applications:This is an excellent solution for cars, motorcycles, trucks, airplanes and mobile Power generator ICEs. This variant is also suited for extreme weather conditions and large altitude and atmospheric temperature/pressure changes. THe solution is also adaptable to almost any type of application.Advantages:

- This solution will provide the highest fuel efficiency theoretical possible for internal combustion engine

- AB Engine Valve-Damper is applicable to single piston or multiple piston engines. One of the great advantages of this implementation is works with “normal” pressures and temperatures of intake gas which simplifies the valve control and allows for inexpensive solutions such as electromagnets for example.

- It simplifies the valve-damper design because it combines two functions, it can be used as a valve that opens and closed at specific times and piston locations or work as a damper creating gas flow resistance at higher engine RPM.

- Excellent for extreme weather conditions and large altitude and atmospheric temperature/pressure changes. The solution is also adaptable to almost any type of application.

- Great engine dynamics

- Easy to adapt to any fuel type

- Engine can start up with gasoline and continue with Diesel

- The best feature of the AB Engine Valve-Damper is that multi-piston engines would only need one valve at the manifold entrance. When acting as a damper it creates gas flow resistance and ensures optimal actual compression for any kind of fuel or intake gas condition. For many ICE applications it is possible to use Valve-Damper without PC controller adjusting fixed Damper position manually for particular fuel type or "summer-winter" intake gas conditions. I would separate it as a Solution 4. This solution is excellent, but not limited, for engines working with constant RPM.

Disadvantages:

- The AB Engine team does not see any significant disadvantages in using an AB Engine Valve-Damper. As this is a highly flexible solution, there is no need to implement it in more rigid ICE applications such as those described in solution one, that is, low power house generators etc...

AB Engine Incorporated

AB Engine Incorporated introduces a New Method (AB Engine Method) to convert burning gasoline, gas or diesel fuels into mechanical energy while still within the bounds of the conventional Otto, Miller, Diesel or similar internal combustion engine (ICE) design constraints. The new method allows for an ICE design with the highest fuel efficiency theoretically possible.

AB Engine was granted by two US Patents: #8,086,386 December 27, 2011 (PDF) and #8,396,645 March 12, 2013

The Company has also China patents #ZL 2008 8 0100951.9 November 14,2012 and patent pending in Europe.

In February 2012, AB Engine Inc. announced that it has designed and completed a high fuel efficiency internal combustion engine (ICE) prototype in order to demonstrate the "proof of principles" behind the AB Engine Technology. Testing the novel AB Engine method and design with an 87 octane rating gasoline yielded 44% higher fuel efficiency in comparison to a similar conventional engine design (see News & Media for details).

AB Engine Incorporated has started licensing activity to the engines production and utilization companies in various industries.

We are licensing the ICE technology which increases fuel consumption efficiency as fundamentally as had been done in the Atkinson's cycle without power depletion and mechanical complexities of Atkinson's design. Our method is applicable to any ICE type, independent of its size, fuel (gasoline, diesel or gas) and including turbocharged and hybrid configurations. AB Engine power output is linear to RPM and limited only by high RPM design constraints.

To see AB Engine Method, please, refer to technology page and technology presentation

|

Please click on the image below to view the Technology page

| ||||||

The AB Engine technology will also improve the efficiency of today’s most efficient vehicle design, the Hybrid design. The combination of the Hybrid design with the AB Engine technology will result in unparalleled mileage per gallon improvements.

Implementing AB Engine technology in turbo-charged engines, Miller type, will deliver powerful and improved efficiency engines as well.

To see the AB Engine Marketing Presentation visit video bellow:

|

Subscribe to:

Posts (Atom)