Frequently Asked Questions

Question 1. Recently we celebrated 100 years of the Otto Internal Combustion Engine Patent. Dozens of huge companies have put enormous funds into what seems like all possible aspects of engine theory, design and practice. What did they miss? What was so hidden from them that made our engine so superior to today’s conventional solutions?

Answer.I want to ensure you that in high tech development there was always room for innovation.....>Full answer

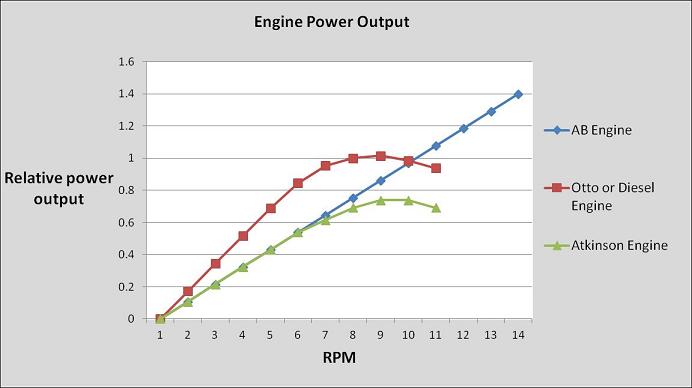

Question 2.It looks like the AB Engine, compared to a conventional engine with the same engine volume burns less fuel for each working cycle. Does this make the AB Engine have a smaller power output? (It was a question from a traditional engine design specialist).

Answer. As it turns out, not at all! On the contrary, an AB Engine can have .....>Full answer

Question 3.What is the actual fuel efficiency of your engine? How much are the fuel savings?

Answer. Independent of the kind of vehicle that the AB Engine will be installed on, including Hybrids, the engine itself will be more efficient with converting burnt fuel to mechanical (or electrical) energy by 25-45%. See a detailed explanation on AB Engine efficiency in comparison to conventional engines.. click here (PDF document)

Question 4.Can your technology be applied for Diesel engines and also benefit their fuel efficiency?

Answer. Yes it will definitely benefit diesel engines. In case of using diesel engines, they will be designed with increased compression/expansion ratios, compared to traditional Diesel engines, and also the AB Engine intake valve with the controller. This will limit the amount of gas so the actual compression of gas will be lowered enough to the point where diesel fuel will be self ignited. For example: if a conventional engine has compression ratio of 16-20 then the AB Engine for diesel fuel with be designed with one of 25-30; this will give increased expansion ratio though fuel efficiency while keeping the diesel burning condition the same as in a conventional diesel engine. The benefits of using the AB Engine technology with diesel fuel are beyond that of just of increased fuel efficiency. Increased design compression ratio will allow (for both gasoline and diesel fuel) simplified piston compression coils and allowed and controlled leaks that will lead to less energy loss on coil friction, this allows for Higher RPM engines with overall increased power output.

Question 5.There are many alternative fuel developments. How is your technology benefiting there? Is your technology necessary in this case?

|